Choosing the right Bitumen 60/70 vs Bitumen 80/100 is the most critical decision for any road construction or paving project. The two most commonly traded grades in the global market are asphalt binder types for roads.

While they may look identical, using the Bitumen 60/70 vs 80/100 wrong grade can lead to disastrous results—like asphalt melting in the summer or cracking in the winter.

At Petroneo, we receive daily inquiries from importers asking: “Which grade should I buy?” In this guide, we break down the technical and practical differences to help you make the right choice.

Table of Contents

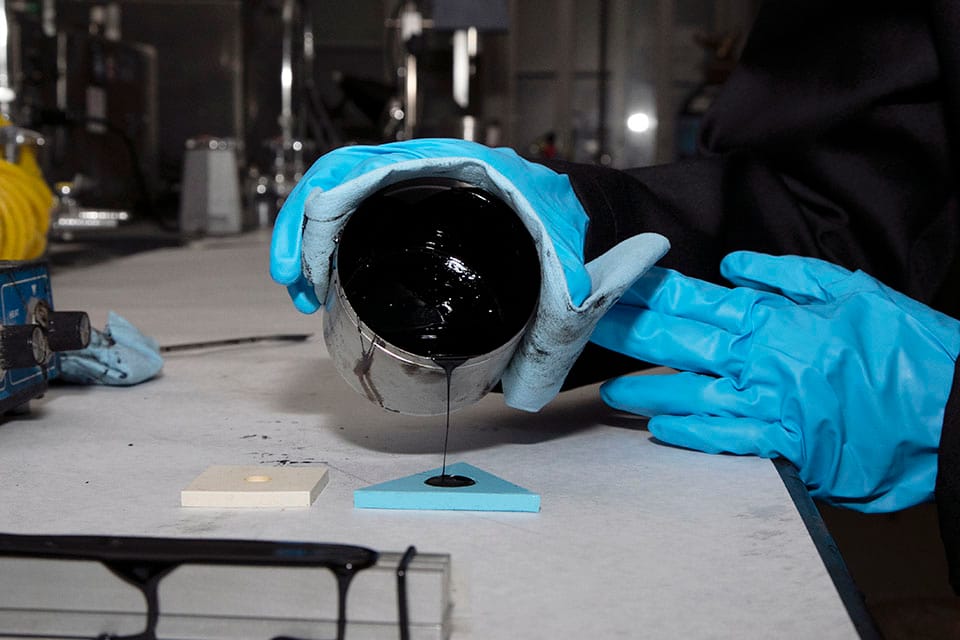

What Do the Numbers Mean? (The Penetration Test)

The numbers “60/70” and “80/100” refer to the hardness of the bitumen. This is measured by a standard test where a needle is allowed to penetrate a bitumen sample.

- penetration grades for road construction: The needle penetrates between 6 mm and 7 mm. It is harder.

- Bitumen 60/70 vs Bitumen 80/100 : The needle penetrates between 8 mm and 10 mm. It is softer.

Rule of Thumb: The lower the number, the harder the bitumen. The higher the number, the softer the bitumen.

Bitumen 60/70 vs 80/100 : Key Differences: Climate and Application

The choice between these two grades depends almost entirely on the climate of the destination country and the traffic load.

1. Bitumen 60/70 vs 80/100 (The “Hot Climate” King)

This is the most widely used grade globally. Because it is harder, it has a higher Softening Point (usually between 49°C to 56°C).

- Best For: Hot and moderate climates (Middle East, Africa, Southeast Asia, Southern Europe).

- Why? It does not soften or deform easily under the scorching sun or heavy truck traffic.

- Risk: If used in very freezing temperatures, it might become too brittle and crack.

2.Bitumen 60/70 vs 80/100 (The “Cold Climate” Specialist)

This grade is softer and more flexible. It has a lower softening point (around 42°C to 52°C).

- Best For: Colder regions (Northern Europe, Canada, parts of Central Asia).

- Why? Its flexibility allows it to expand and contract without cracking during freezing winters.

- Risk: If used in a very hot desert, the road might become soft and “rut” (create grooves) under heavy tires.

Technical Comparison Table

| Property | Unit | Bitumen 60/70 | Bitumen 80/100 | Test Method |

|---|---|---|---|---|

| Penetration @ 25°C | 0.1 mm | 60 – 70 | 80 – 100 | ASTM D5 |

| Softening Point | °C | 49 – 56 | 42 – 52 | ASTM D36 |

| Ductility @ 25°C | cm | Min 100 | Min 100 | ASTM D113 |

| Flash Point | °C | Min 232 | Min 230 | ASTM D92 |

| Solubility in TCE | % wt | Min 99.0 | Min 99.0 | ASTM D2042 |

Note: Petroneo guarantees that all our cargoes meet international ASTM standards, verified by SGS or Geo-Chem inspections at the port of loading.

Packaging and Shipping Options Bitumen 60/70 vs 80/100

Whether you choose grade 60/70 or 80/100, the packaging options remain the same. As an importer, your choice affects the final price per ton.

- New Steel Drums: The most popular choice for traders. Easy to handle and store. (Standard: 180kg +/- 3kg).

- Jumbo Bags (Poly Bags): A cost-effective solution. 1-ton bags that melt along with the bitumen. No waste, lower freight cost.

- Bulk (Vessel): For large-scale government projects (usually 2000+ MT).

Conclusion: Which One Should You Order?

- Choose Bitumen 60/70 vs 80/100 : Your project is in a warm region orhandles heavy highway traffic. It offers superior durability against heat.

- Bitumen 60/70 vs 80/100 : Your project is in a region with cold winters. Its flexibility will prevent thermal cracking.

Ready to Order?

At Petroneo, we supply premium grade Bitumen from the Middle East to global ports. We handle the sourcing, inspection, and logistics.