Understanding Benzene Toluene Xylene Supply Dynamics for Your Business

Navigating the complexities of benzene toluene xylene supply requires a thorough understanding of market forces, logistical constraints, and the specific needs of various industries. Whether you’re sourcing these essential aromatic hydrocarbons for chemical synthesis, solvent applications, or fuel additives, a reliable supply chain is paramount to your operational success. This comprehensive guide will delve into the critical aspects of benzene toluene xylene supply, equipping you with the knowledge to make informed procurement decisions.

Executive Summary

- Benzene toluene xylene supply chains are influenced by crude oil prices, refinery output, geopolitical events, and global demand from key end-user industries like petrochemicals, plastics, and coatings. Understanding these interconnected factors is crucial for strategic sourcing and price forecasting.

- Careful consideration of specifications and grades (e.g., purity levels, specific isomer ratios for xylene) is essential to ensure the sourced benzene, toluene, and xylene meet the precise requirements of their intended applications, preventing process inefficiencies or product quality issues.

- Packaging and palletization methods, including drums, IBCs (Intermediate Bulk Containers), and bulk shipments, must align with safety regulations, handling capabilities, and the volume requirements of buyers to ensure efficient and secure delivery.

- Familiarity with common Minimum Order Quantities (MOQs) and typical lead times, which can range from days to weeks depending on supplier, product availability, and shipping complexity, is vital for effective production planning and inventory management.

- Compliance with international shipping regulations, trade treaties, and the provision of accurate documentation such as Certificates of Analysis (COAs), Material Safety Data Sheets (MSDS), and Bills of Lading are non-negotiable for a smooth and legal benzene toluene xylene supply.

Specifications and Grades Benzene toluene: Meeting Your Purity Requirements

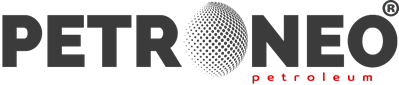

The fundamental requirement for any successful procurement of benzene, toluene, and xylene lies in accurately defining and meeting the necessary specifications and grades. These aromatic hydrocarbons, often collectively referred to as BTX aromatics, serve as vital building blocks and solvents across a wide spectrum of industrial applications. Each compound – benzene, toluene, and xylene – has distinct chemical properties and purity requirements depending on its end-use.

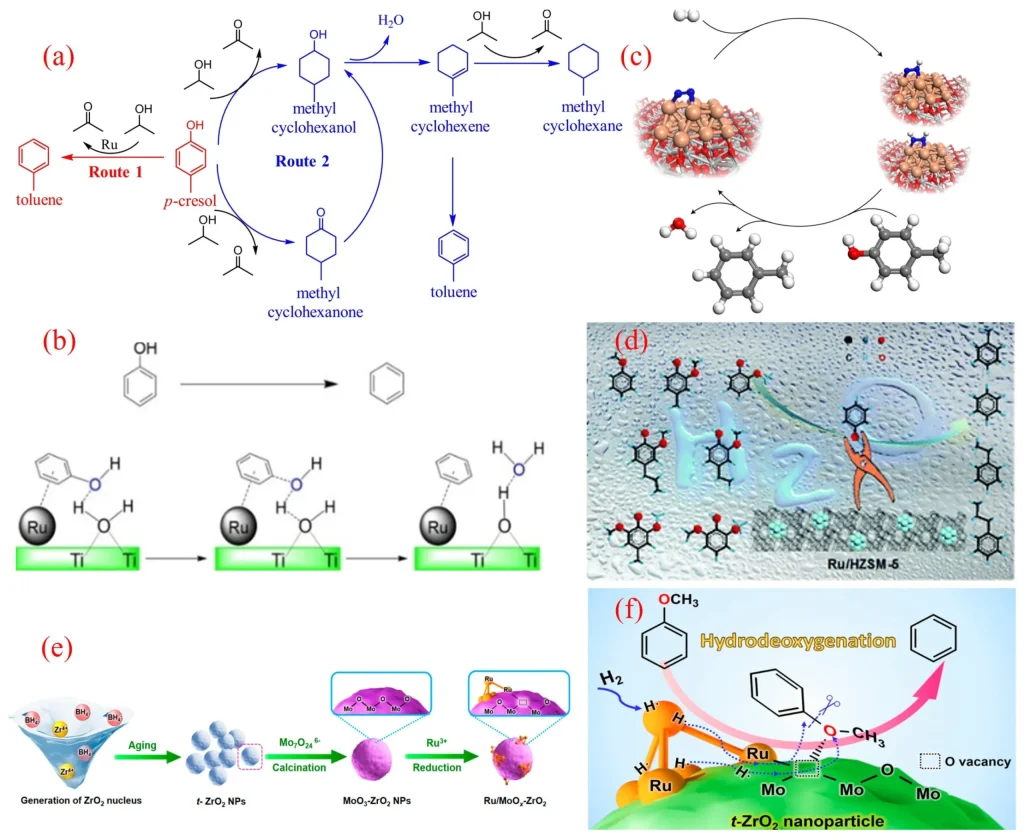

Benzene, for instance, is a primary feedstock for styrene, phenol, and cyclohexane, which in turn are used to produce polystyrene, polycarbonates, and nylon. Toluene finds its way into the production of polyurethane, as a solvent in paints and lacquers, and as an octane booster in gasoline. Xylene, typically supplied as a mixed isomer (ortho-, meta-, para-xylene) or as specific isomers, is crucial for producing plastics like PET (via para-xylene), and as solvents in printing inks and adhesives.

Suppliers will often offer various grades characterized by their purity levels. For example, industrial-grade benzene might have a purity exceeding 99.5%, while technical grades for specific syntheses could require higher purities or tighter controls on trace impurities. Similarly, toluene and mixed xylenes are available in different specifications, with the distinction between ortho-, meta-, and para-xylene being particularly important for xylene sourcing. Understanding these differences allows buyers to select the most cost-effective and functionally appropriate material for their process.

Packaging and Palletization Benzene toluene : Ensuring Safe and Efficient Handling

The physical presentation and containment of benzene, toluene, and xylene are critical for safe handling, storage, and transport. The choice of packaging directly impacts logistics efficiency, safety protocols, and potential environmental risks. Suppliers of benzene toluene xylene supply materials typically offer a range of options to accommodate different buyer needs and regulatory requirements.

Common packaging formats for these liquid aromatic hydrocarbons include:

- Steel Drums: Typically ranging from 200-250 liters (approximately 55-65 gallons), these drums are robust and suitable for medium-sized orders. They are often secured on pallets for easier handling with forklifts.

- Intermediate Bulk Containers (IBCs): Also known as totes, IBCs are usually 1,000-liter (approximately 275-gallon) capacity units. They consist of a metal cage surrounding a plastic inner tank, offering a more efficient way to handle larger volumes than individual drums. IBCs are designed for easy stacking and forklift maneuverability.

- Bulk Shipments: For very large volumes, benzene, toluene, and xylene are transported via dedicated road tankers, railcars, or specialized chemical tankers for sea freight. This method is the most cost-effective per unit but requires significant infrastructure at both the supplier and buyer’s end.

Palletization is a standard practice for drums and IBCs. Drums are often strapped to wooden or plastic pallets, typically 4 or 8 per pallet, allowing for safe stacking and movement. IBCs are generally stored and transported on their integrated pallets. Proper labeling according to international hazardous materials regulations (e.g., UN numbers, hazard pictograms) is a mandatory part of the packaging and palletization process.

Minimum Order Quantity (MOQ) and Lead Times: Planning for Production Continuity

When securing your benzene toluene xylene supply, understanding the supplier’s Minimum Order Quantity (MOQ) and typical lead times is essential for effective production planning and inventory management. These parameters vary significantly between suppliers, geographical locations, and the specific products being sourced. Negotiating these terms strategically can prevent costly disruptions.

Minimum Order Quantity (MOQ):

MOQs are the smallest quantity a supplier is willing to sell in a single transaction. For bulk commodities like benzene, toluene, and xylene, MOQs can be substantial.

- Drums/IBCs: MOQs might be as low as a few drums or IBCs for some distributors, while larger manufacturers may have MOQs equivalent to a partial truckload or full container load (FCL).

- Bulk Shipments: For road or rail tankers, the MOQ is typically the capacity of one vehicle. For sea freight, it often starts from a full container load (FCL) for smaller parcels, up to full vessel loads for major consumers.

Lead Times:

Lead times refer to the duration between placing an order and receiving the goods. Several factors influence this:

- Product Availability: Is the specific grade of benzene, toluene, or xylene in stock at the supplier’s facility or at a nearby terminal?

- Production Schedules: If the material needs to be produced, lead times will be longer, especially for specialized grades.

- Transportation: Transit times, port congestion, customs clearance, and the availability of suitable transport (tankers, trucks) all contribute to the overall lead time.

- Geographical Location: Proximity to the supplier and efficient logistical routes play a significant role.

Indicative lead times can range from 1-2 weeks for readily available products from local distributors to 4-8 weeks or more for international bulk shipments or custom-blended materials. It’s crucial to communicate your production schedules to your supplier to ensure alignment and avoid stock-outs or excess inventory.

Documentation and Compliance: Navigating Regulatory Landscapes

Ensuring smooth and compliant benzene toluene xylene supply hinges on meticulous documentation and adherence to a complex web of international and national regulations. For hazardous materials like benzene, toluene, and xylene, this is not merely a procedural step but a critical aspect of safety, legality, and environmental responsibility. Buyers must be prepared to receive and review a suite of documents, and suppliers must rigorously provide them.

Essential Documentation:

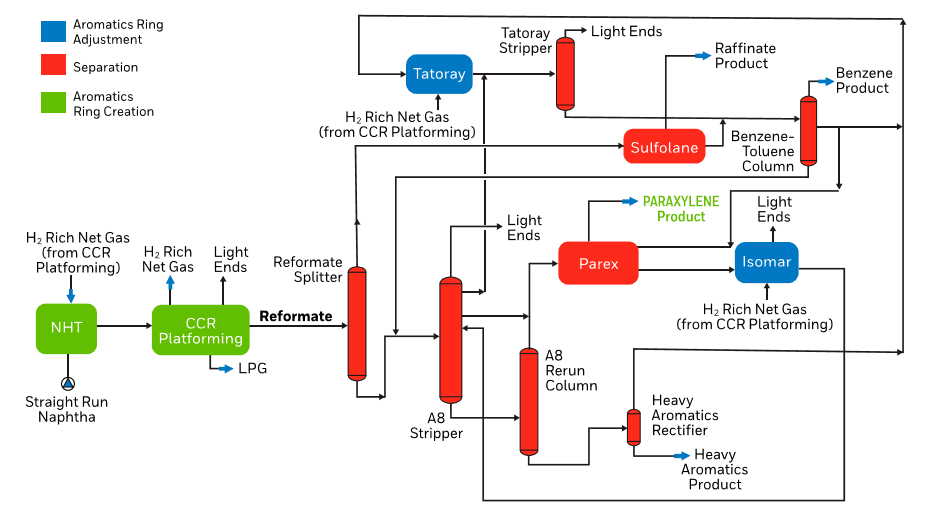

- Certificate of Analysis (COA): This document confirms that a specific batch of product meets the agreed-upon specifications. It details key parameters such as purity, specific gravity, boiling range, and the concentration of any impurities. A COA is vital for quality control and to verify that the product is fit for its intended use.

- Material Safety Data Sheet (MSDS) / Safety Data Sheet (SDS): The SDS provides comprehensive information on the chemical’s properties, hazards, safe handling procedures, emergency measures, and disposal recommendations. It is a critical document for workplace safety and regulatory compliance.

- Bill of Lading (BOL) / Air Waybill (AWB): For shipments, these documents serve as the contract of carriage between the shipper and the carrier. They provide details about the cargo, origin, destination, and terms of transportation.

- Commercial Invoice: This is a standard invoice detailing the sale, including quantities, prices, and terms of payment.

- Packing List: Outlines the contents of each package (drum, IBC, pallet), including net and gross weights, and shipping marks.

Key Compliance Areas:

- Hazardous Materials Transportation Regulations: Compliance with bodies like the IMO (International Maritime Organization) for sea freight, IATA (International Air Transport Association) for air freight, and national road/rail regulations is mandatory. This includes correct classification, packaging, marking, labeling, and documentation.

- Chemical Registration and Import/Export Controls: Depending on the regions of origin and destination, chemicals like benzene, toluene, and xylene may be subject to regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe or TSCA (Toxic Substances Control Act) in the United States. Understanding these can impact sourcing options and timelines.

A comprehensive understanding of these documentation and compliance requirements ensures that your benzene toluene xylene supply is not only reliable but also legally sound and safe.

Logistics and Incoterms: Optimizing Your Global Transportation

The efficient and cost-effective delivery of benzene, toluene, and xylene relies heavily on understanding global logistics and the agreed-upon Incoterms. These terms define the responsibilities, costs, and risks associated with the transportation of goods from seller to buyer. Choosing the right Incoterm is crucial for managing your budget and ensuring a smooth supply chain.

Common Incoterms for Benzene, Toluene, Xylene Supply:

- EXW (Ex Works): The buyer assumes almost all responsibility and costs, including loading at the seller’s premises, transportation, insurance, and import duties. This offers the buyer maximum control but also maximum risk and administrative burden.

- FOB (Free On Board): The seller delivers the goods to the named port of shipment, clears them for export, and places them on board the vessel nominated by the buyer. Once on board, the risk and costs transfer to the buyer. This is a very common term for international sea freight.

- CIF (Cost, Insurance, and Freight): The seller pays for the cost of the goods, insurance, and freight to the named destination port. The risk transfers to the buyer when the goods are loaded on board the vessel at the origin. The buyer is responsible for import clearance and any costs from the destination port onwards.

- DAP (Delivered At Place): The seller delivers the goods to the buyer at a mutually agreed-upon destination, ready for unloading. The seller bears all risks and costs associated with bringing the goods to that point, excluding import duties and taxes.

Logistical Considerations:

- Mode of Transport: Benzene, toluene, and xylene are typically transported by sea in bulk chemical tankers, by rail in tank cars, by road in tank trucks, or in drums/IBCs via container ships. The choice depends on volume, distance, cost, and infrastructure availability.

- Storage and Handling: As flammable liquids, benzene, toluene, and xylene require specialized storage facilities, including bunded areas, appropriate ventilation, and safety equipment.

- Port Operations and Customs: Navigating port procedures, customs inspections, quarantine, and duties at both origin and destination can significantly impact delivery timelines and costs.

Selecting the appropriate Incoterm and understanding the logistical intricacies will ensure your benzene toluene xylene supply is managed with maximum efficiency and minimal risk.

Risk Management and Claims: Protecting Your Investment

Securing a consistent benzene toluene xylene supply involves more than just placing an order; it requires proactive risk management and a clear process for handling claims. Despite careful planning, disruptions can occur, leading to quality issues, delays, or damage. Having robust procedures in place protects your business and ensures accountability.

Identifying Potential Risks:

- Quality Deviations: The delivered product may not meet the agreed-upon specifications. This can arise from contamination during transit, improper storage by the supplier, or errors in production.

- Transportation Delays: Weather events, port strikes, customs hold-ups, or vessel issues can cause significant delays, impacting your production schedules.

- Damage During Transit: Improper packaging, mishandling, or accidents can lead to spills or container damage.

- Supplier Solvency or Reliability Issues: In rare cases, suppliers may face financial difficulties or cease operations, impacting future supply.

- Geopolitical Instability: Conflicts, trade disputes, or sanctions can disrupt global supply chains and affect availability and pricing.

Handling Claims:

- Immediate Notification: If you identify a quality issue or damage upon receipt, notify the supplier and the carrier immediately. Document the issue thoroughly with photographs and detailed descriptions.

- Gather Evidence: Collect all relevant documentation, including the COA, BOL, inspection reports, and any correspondence with the supplier or carrier. For quality claims, retain samples of the affected product.

- Follow Contractual Procedures: Review your purchase agreement and the applicable Incoterms for stipulated claim procedures and time limits.

- Formal Claim Submission: Submit a formal written claim to the responsible party (supplier for quality, carrier for transit damage) within the agreed-upon timeframe.

- Negotiation and Resolution: Work with the supplier or carrier to resolve the claim, which may involve a refund, replacement, or compensation for losses incurred.

- Third-Party Inspection: If disagreements arise, consider engaging an independent, accredited third-party inspector to assess the quality or damage.

A proactive approach to risk management, coupled with a clear and efficient claims process, is fundamental to safeguarding your benzene toluene xylene supply arrangements and maintaining operational continuity.

Conclusion

The global market for benzene, toluene, and xylene is dynamic and multifaceted, requiring buyers to engage with a deep understanding of its intricacies. From stringent purity specifications and reliable packaging solutions to navigating complex logistics and regulatory frameworks, every element of your benzene toluene xylene supply chain demands careful consideration. By prioritizing clear communication with suppliers, meticulous documentation, proactive risk management, and strategic negotiation of terms like MOQs and lead times, you can build a resilient and efficient sourcing strategy. Ultimately, a well-managed benzene toluene xylene supply is not just about acquiring raw materials; it’s about securing the foundation for consistent, high-quality production and sustained business growth.