S-PVC for Construction: Certificates, QC & Anti-Dumping Notes

Navigating the global market for S-PVC for Construction demands a keen understanding of Certificates, QC & Anti-Dumping Notes. This comprehensive guide will equip you with the essential knowledge, from understanding K-value to the intricacies of anti-dumping duties and the final landing steps for your claims.

Executive Summary

- Quality Assurance: Emphasizes the critical role of S-PVC export certificates and rigorous EU quality checks to ensure material suitability for construction projects.

- Regulatory Landscape: Highlights the importance of understanding BIS India standards and anti-dumping regulations, particularly for imported S-PVC.

- Documentation Essentials: Outlines the necessary documentation, including Material Safety Data Sheets (MSDS) and Certificates of Analysis (COA), for seamless import and claims.

- Logistical Due Diligence: Covers key aspects of landing steps, Incoterms, and best practices for managing logistics to mitigate risks.

- Trade Compliance: Provides insight into anti-dumping investigations and how to manage potential claims effectively.

Understanding S-PVC: Grades and Specifications

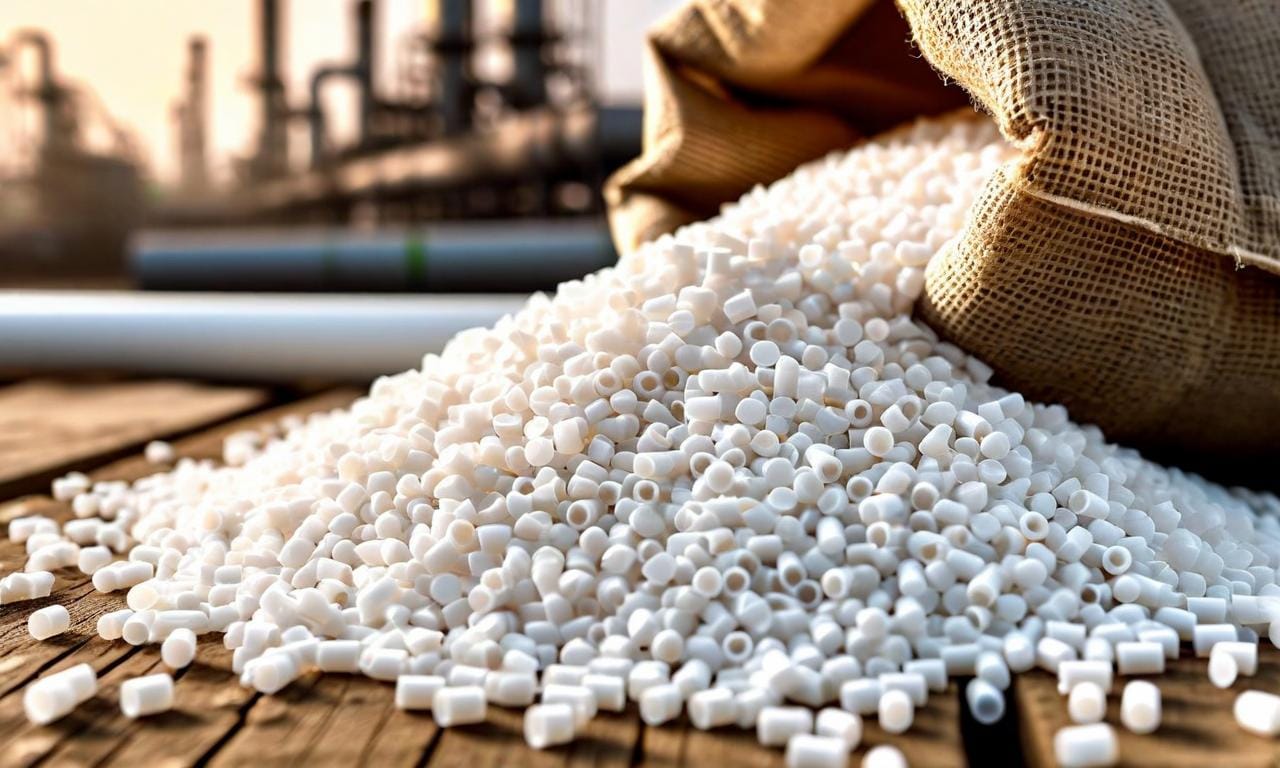

Polyvinyl Chloride (PVC) is a versatile polymer widely used in the construction industry. Suspension PVC (S-PVC) is the most common type, produced via suspension polymerization. Its properties can be tailored through formulation and processing, making it suitable for a vast array of applications such as pipes, window profiles, flooring, cables, and roofing membranes. The key to selecting the right S-PVC grade lies in understanding its technical specifications, most notably the K-value.

The K-value (also known as Fikentscher K-value) is a measure of the average molecular weight of the PVC resin. A higher K-value typically indicates a higher molecular weight, which translates to improved mechanical strength, better chemical resistance, and increased thermal stability. For construction applications, K-values generally range from 55 to 75. For instance, lower K-values (around 55-60) are often preferred for rigid applications like pipes and profiles due to their processability and flow characteristics. Higher K-values (68-75) are better suited for flexible applications where enhanced durability and toughness are required, such as flooring or roofing membranes.

Beyond the K-value, other critical specifications include:

- Particle Size Distribution: Affects processing behavior and the surface finish of the final product.

- Bulk Density: Influences handling and storage.

- Volatile Matter Content: Indicates the presence of residual monomers or solvents, impacting safety and product performance.

- Plasticizer Absorption: Relevant for flexible PVC formulations.

When procuring S-PVC for construction, obtaining a detailed technical data sheet (TDS) from the manufacturer is paramount. This document will outline all relevant specifications, ensuring the material meets the performance requirements of your intended application and complies with regional standards like BIS India.

PVC Export Certificates and EU Quality Checks

For international trade, PVC export certificates are non-negotiable. These documents serve as official declarations that the S-PVC resin meets specific quality, safety, and regulatory requirements of both the exporting and importing countries. For European markets, strict EU quality checks are in place. These often involve verification against standards like EN 741 (for general-purpose PVC) and specific directives related to environmental impact and chemical safety, such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

A typical set of required certificates might include:

- Certificate of Analysis (COA): Provided by the manufacturer, this document details the specific batch test results against the agreed specifications, including K-value, particle size, and volatile matter.

- Material Safety Data Sheet (MSDS) / Safety Data Sheet (SDS): Essential for safe handling, storage, and transportation. It provides information on potential hazards, first-aid measures, and disposal.

- Product Origin Certificate: Verifies where the S-PVC resin was manufactured.

- Quality Certificates: These may include ISO certifications for the manufacturing facility, demonstrating adherence to international quality management standards.

For markets like India, compliance with Bureau of Indian Standards (BIS) is crucial. BIS certification signifies that the S-PVC product conforms to relevant Indian standards for its intended application, such as those for pipes or electrical insulation. Failing to secure the correct PVC export certificates can lead to significant delays, rejections at customs, and substantial financial losses, impacting the crucial landing steps for your project.

Packaging, Palletization, and Shipping

The integrity of S-PVC during transit is heavily dependent on proper packaging and palletization. Manufacturers typically supply S-PVC in either:

- 25 kg multi-layer paper bags: The most common packaging for smaller quantities, easy to handle and store.

- Jumbo bags (Bulk bags) / Flexible Intermediate Bulk Containers (FIBCs): These large bags, typically holding 500 kg to 1,500 kg, are used for larger volumes and require specialized handling equipment. They are often lined with polyethylene to protect against moisture.

For international shipments, these bags are usually stacked and secured on wooden pallets. Pallets are often shrink-wrapped to provide an extra layer of protection against dust, moisture, and tampering. The palletization arrangement is critical for efficient container loading and stability during ocean freight. Proper stacking and securing minimize the risk of bag rupture or contamination, ensuring the S-PVC arrives at its destination in optimal condition for processing.

Quality Control (QC) in Packaging: Reputable suppliers implement stringent QC measures even at the packaging stage. This includes checking bag integrity, proper sealing, accurate weight labeling, and secure palletization. For S-PVC destined for markets with stringent regulations, such as EU quality checks, ensuring the packaging materials themselves are compliant and do not introduce contaminants is also important.

Minimum Order Quantities and Lead Times

Understanding Minimum Order Quantities (MOQs) and lead times is vital for effective project planning when procuring S-PVC.

- MOQ: For standard S-PVC grades, MOQs can range from a full container load (FCL), typically 20-24 metric tons, down to smaller less-than-container loads (LCL) for specialized or smaller projects, though LCL shipments often incur higher per-unit shipping costs. Manufacturers may be flexible on MOQs for established clients or specific market demands.

- Lead Times: Lead times for S-PVC can vary significantly based on the supplier’s production schedule, raw material availability, current market demand, and the destination port. A typical lead time from order confirmation to dispatch might range from 2 to 6 weeks. This timeframe does not include transit time, which can add another 2 to 6 weeks depending on the shipping route.

Factors influencing longer lead times include:

- Production planning for specific K-value grades.

- Seasonal demand fluctuations.

- Customs clearance procedures at the destination.

- Port congestion.

It is advisable to factor in buffer time for unexpected delays, especially when dealing with critical project timelines. Clear communication with the supplier regarding your expected delivery schedule is crucial.

Documentation and Compliance: The Backbone of Your Transaction

For any international trade involving S-PVC for construction, a robust set of documentation is the bedrock of a smooth transaction. Missing or incorrect documents can lead to significant delays, fines, and even seizure of goods. This is where understanding S-PVC for Construction: Certificates, QC & Anti-Dumping Notes becomes critical.

Key documents you will need to manage and verify:

- Commercial Invoice: Details the transaction, including quantities, prices, and payment terms.

- Bill of Lading (B/L) or Air Waybill (AWB): Evidence of shipment and title to the goods.

- Packing List: Specifies the contents of each package and pallet.

- Certificate of Origin: Confirms the country where the S-PVC was manufactured.

- Certificate of Analysis (COA): As mentioned earlier, confirms batch quality.

- Material Safety Data Sheet (MSDS/SDS): For safe handling and regulatory compliance.

- Insurance Certificate: If required by Incoterms or letter of credit.

- EIA Certificate (Environmental Impact Assessment): Increasingly required by some importing nations.

- BIS India Registration/Certification: If importing into India and the product falls under BIS purview.

- REACH Compliance Statement/Registration: For imports into the European Union.

Internal Compliance Checklist:

- [ ] Verify all PVC export certificates align with purchase order specifications.

- [ ] Cross-reference COA batch numbers with packing lists and B/L.

- [ ] Ensure MSDS is current and available in the required language.

- [ ] Confirm BIS India compliance documentation is in order (if applicable).

- [ ] Review EU quality checks statements or relevant declarations for EU shipments.

- [ ] Check for any required import permits or licenses.

- [ ] Confirm supplier’s adherence to anti-dumping regulations for the target market.

Proper documentation management ensures that your S-PVC can clear customs efficiently, meet all quality mandates, and lay the groundwork for any future claims should they arise, especially in the context of complex anti-dumping investigations.

Logistics and Incoterms: Ensuring Smooth Landing Steps

Efficient logistics are paramount for ensuring that your S-PVC arrives safely and on schedule, impacting the critical landing steps of your supply chain. The chosen Incoterm sets the responsibilities for freight, insurance, customs, and risk transfer between the buyer and seller.

Common Incoterms for S-PVC shipments include:

- FOB (Free On Board): The seller delivers the goods on board the vessel nominated by the buyer. The buyer bears all costs and risks of loss of or damage to the goods from that point.

- CIF (Cost, Insurance, Freight): The seller pays for the cost, insurance, and freight to bring the goods to the named port of destination. Risk transfers when the goods are on board the vessel.

- EXW (Ex Works): The seller makes goods available at their premises. The buyer bears all costs and risks from this point, including loading. This offers flexibility but places maximum responsibility on the buyer.

- DDP (Delivered Duty Paid): The seller delivers the goods to the buyer at the named place of destination, cleared for import and ready for unloading. This is the most comprehensive term for the buyer but carries the highest risk for the seller.

When considering S-PVC for construction, especially under strict EU quality checks or for markets like BIS India, clear understanding of who handles customs clearance and import duties is vital.

Transit and Customs: Depending on the Incoterm, either the buyer or seller will manage the freight booking, cargo insurance, and customs clearance process. This involves preparing and submitting the required documentation, including PVC export certificates, to customs authorities. Delays in customs can be a major bottleneck, impacting project timelines. Maintaining open communication channels with your freight forwarder and customs broker is essential for a smooth transition through these landing steps.

Addressing Risks: Claims and Anti-Dumping Challenges

Despite meticulous planning, risks are inherent in international S-PVC trade. Understanding how to manage potential claims and navigate anti-dumping measures is crucial for protecting your investment and project timelines.

Product Claims: Claims can arise if the delivered S-PVC does not conform to the agreed specifications (e.g., incorrect K-value, contamination, damage during transit). A clear process for raising claims should be established:

- Immediate Notification: Inform the supplier and shipping line (if applicable) immediately upon discovering the non-conformity.

- Documentation: Gather evidence such as photographic proof, third-party inspection reports, and updated analysis results.

- Formal Claim Submission: Submit a formal written claim detailing the issue, the non-conformity with contractual specifications, and the desired resolution (e.g., refund, replacement, price adjustment).

- Arbitration/Mediation: If a resolution cannot be reached, international arbitration or mediation may be necessary.

Anti-Dumping Notes: Anti-dumping duties are special tariffs imposed by a country on imported goods that are sold at less than their fair market value and cause injury to domestic industries. If S-PVC is subject to anti-dumping measures in your target market, it can significantly increase the cost of imports.

- Investigation Process: Anti-dumping investigations are typically initiated by a domestic industry complaint. During the investigation, authorities will examine export prices, normal values, and injury to the domestic industry.

- Indicative Tariffs: If anti-dumping is found, specific duties (often a percentage of the CIF value) will be applied to S-PVC from specific exporting countries. These duties are not fixed and can change following reviews.

- Impact on Imports: These duties add considerable cost, potentially making imports unviable or requiring renegotiation of sales contracts. Buyers need to stay informed about current and potential anti-dumping measures impacting their S-PVC sourcing.

- Compliance: Suppliers must provide accurate pricing and cost information to avoid being subject to adverse facts available or higher dumping margins. Likewise, importers need to ensure their declared landed costs are accurate to align with duties.

Navigating issues of anti-dumping requires close collaboration with your supplier and potentially trade consultants. Understanding these complexities ensures that your landing steps and any subsequent claims processes are managed effectively, even when dealing with challenging trade policies.

Conclusion: Securing Your S-PVC Material

Successfully sourcing S-PVC for construction hinges on a thorough understanding of technical specifications, adherence to stringent quality controls, diligent management of documentation, and awareness of regulatory landscapes. From deciphering K-value to fulfilling BIS India requirements or meeting rigorous EU quality checks, every step is critical.

Mastering the nuances of PVC export certificates, navigating anti-dumping regulations, and ensuring smooth landing steps for your materials empowers you to make informed purchasing decisions. By prioritizing quality, compliance, and clear communication, you can secure the reliable supply of S-PVC essential for your construction projects.

For businesses seeking expert guidance and seamless procurement of S-PVC for Construction: Certificates, QC & Anti-Dumping Notes, partnering with experienced suppliers is key to mitigating risks and ensuring project success.